about us

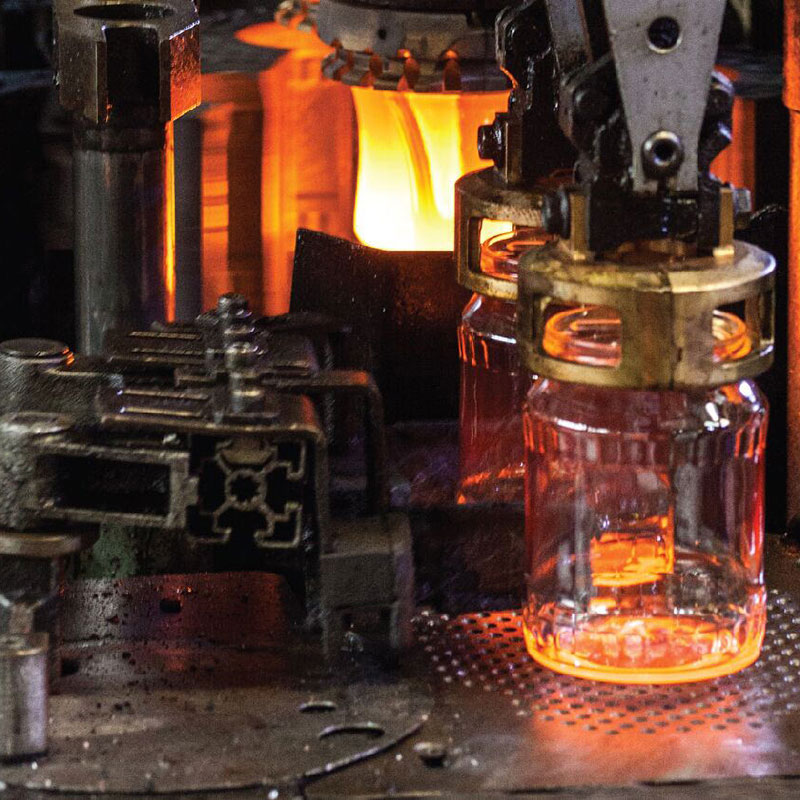

Moulding Area

We offer a comprehensive approach to improving project delivery

The entire moulding and packaging area is ISO 8 (Class 1,00,000) to eliminate the possibility of foreign particles in the finished product.

The plan has an installed capacity of 100 TR of AHU's with HEPA filters of 0.3 micron to ensure that all the production areas have a comfortable working environment which also complies with clean room requirements.

We have IBM (Injetion Blow Moulding), EBM (Extrusion Blow Moulding), IM (Injection Moulding) and ISBM (Injection Strectch Blow Moulding)

Apart from the above we have aluminium ROPP cap manufacturing machine (Recon make), automatic flip top closing machine, automatic ring and wad assembly machine and semi automatic corrugated box manufacturing facilities at our facility at Karnal, haryana.